Changing your maintenance plan from quarterly or annual buff and wax to a ceramic coating may be intimidating.

The market is flooded with options claiming the product will make your yacht look brand new and easier maintenance. So, how do you find the best solution for your yacht?

This brings us to the story of Tony and his 2017 66’ Azimut. After diligently researching for the best yacht ceramic coating protection, Tony selected Glidecoat.

In this case study, we will walk through his before and after journey of selecting Glidecoat to help you and other yacht owners.

- Brand:

- Azimut

- Length:

- 66'

- Year:

- 2017

- Location:

- West Palm Beach, FL

As a yacht owner, you face a number of hurdles when evaluating the best options to maintain your yacht. For 30 - 40 years, a vast majority of yacht owners, selected the traditional maintenance program of buffing and waxing their yacht to protect from the harsh marine conditions.

As I am sure you have experienced yourself, wax does not hold up well over time. Wax can’t hold up for a number of reasons;

• Does not bond with the pores of the surface

Wax is similar to sunscreen as it simply sits on the surface, not filling in the pores and bonding with the surface. This means that every time the boat is used, rinsed, or washed, you are effectively removing a layer of wax from the surface. As a result, salt and water will be able to get into the pores of the surface and start to cause damage

• Wax begins to evaporate at 110°F

Here in South Florida, it is quite common for the surface of the yacht to be exposed to temperatures greater than 110°F. And, at this temperature, wax will begin to evaporate, whereas, the Glidecoat ceramic coating can withstand exposure to temperatures greater than 1000°F

• At best: wax is only a temporary solution

Wax is truly only effective here in South Florida if you are re-applying every 6-8 weeks, and in some cases, sooner then that. As just mentioned above, with the wax not bonding directly to the surface, and therefore, common use of the boat with exposure to water abrasion, salt, cleaning, etc, will contribute to removing the wax. Without any protection on the surface, your boat will start to experience the repercussions.

Back To Tony's Story

What’s interesting with Tony’s story, is he was first exposed to ceramic coatings by a friend. His friend had applied a ceramic coating to his high end vehicle and was amazed by the results.

But, upon researching ceramic coatings, he discovered an extensive number of options for the automotive sector, but much less that are strictly focused in the marine industry.

For any yacht/boat owner who is considering a ceramic coating to be applied to your boat, make sure to thoroughly research the product.

Applying a ceramic coating to a yacht/boat is vastly different than an automobile and you should consider a coating that has been optimized for marine use.

Here at Glidecoat, we developed our yacht ceramic coating protection product since 2012 to specifically battle the harsh marine conditions. Our proprietary formula is designed to battle high temperatures, constant exposure to salt, chemicals and UV damage.

Now, let's get back to Tony's story and the process of applying our yacht ceramic coating protection product to his 66' Azimut.

The project included applying our ceramic coating to;

• Hull

• All stainless steel metal and railings

• Transom

• All exterior facing fiberglass on the top side and superstructure

The project presented a unique challenge of completing the work in the water with the use of a raft.

See the photos below, as upon first starting the work on the 66' Azimut, we encountered salt all over the hull, considerable amount of dirt and watermarks on the surface, swirl marks and scratches from previous detailing jobs and inconsistent gloss meter readings.

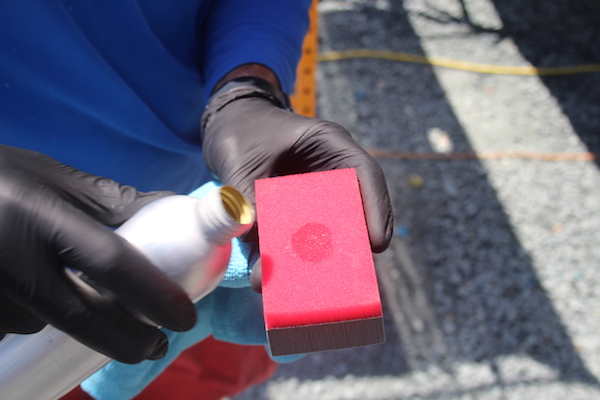

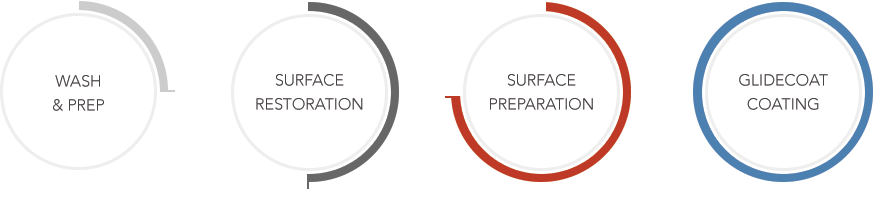

The process of yacht ceramic coating protection is laborious and the team must be diligent to deliver quality results.

When our team is working on a yacht/boat, our process at a minimum is 5 steps and can range to 8 - 10 steps depending on the condition of the surface.

An important aspect to keep in mind with ceramic coatings, is that preparation and restoration is absolutely essential. The ceramic coating is simply locking in the condition of the surface after the restoration steps.

Our process here at Glidecoat is to use a gloss meter to measure the current shine of the surface. When we first arrive at a boat, we take gloss meter reading in various areas of the boat to get an understanding of the necessary restoration steps.

For Tony’s boat, the gloss meter readings were inconsistent and ranged from 38.9 on the hull to 75.9 on the transom.

Inconsistent gloss meter readings are normal for boats with wax because the surface is not protection from the harsh conditions and areas that are highly exposed to salt and water will suffer more.

The use of the gloss meter has numerous benefits;

1. Provides numerical evidence of the surface shine

A brand new yacht/boat out of factory will have gloss meter readings of 82 - 88. If the surface is paint, you will typically see slightly higher gloss meter readings than gel coat.

2. Check the performance of the Glidecoat ceramic coating

From our laboratory and field testing, we guarantee the gloss meter readings will not go below 30% after the ceramic coating application. Therefore, as with Tony’s boat, the gloss meter readings were registering at 97.4.

We guarantee the gloss meter readings in 18 months will be higher than 68.

With the inconsistent gloss meter readings across the yacht, we began our restoration process by using our Nano Compound with a light cutting foam pad to remove the salt, water marks and bring an added depth to the gloss of the black hull.

Now comes the real transformation.

At this point, we have finished the restoration process to bring back the shine and color of the hull. Before applying our gelcoat ceramic coating, we use Surface Wipe, our version of a denatured alcohol to sterilize the surface and ensure all contaminants are removed from the surface.

With the surface now fully prepared and consistent we started the application of our gelcoat ceramic coating.

Applying two (2) coats of our marine ceramic coating, the coating will fill in all of the pores of the surface and after 8 hours of curing time, will create a protective barrier on the hull to prevent oxidization and hard water marks.

After the curing process, the hull of the yacht looks like glass!