Product Testing

Becoming a leader in surface restoration and protection, didn't happen by accident. Glidecoat has invested heavily in testing its coatings through independent labs, before introducing them to the market.

Obviously, there is no testing that can equal actual real-life results (you can read those in our case study section), but the extreme combination of accelerated weather testing as well as atmospheric exposure testing, as well as submergence and fouling testing come close.

Florida is the internationally recognized benchmark location for outdoor exposure testing. Florida subtropical weathering exposures are not only realistic, they are also accelerated. One year of Florida sunshine can equate to several years of weathering elsewhere. Florida has high-intensity sunlight, high annual UV, high year round temperatures, abundant rainfall and very high humidity.

It is this synergistic effect of UV, moisture and heat that makes the South Florida area the ideal location for testing durability of our coatings in outdoor environments.

The extremely sunny, humid, and warm climate has been proven especially useful for the types of testing we use including:

- Color change, fading, and gloss loss

- Cracking, peeling, chalking, and blistering

- Mechanical strength loss and physical deterioration

- Moisture sensitivity of our coatings

- Biodegradation, including mold, mildew, fungus and algae

- Accelerated corrosion testing

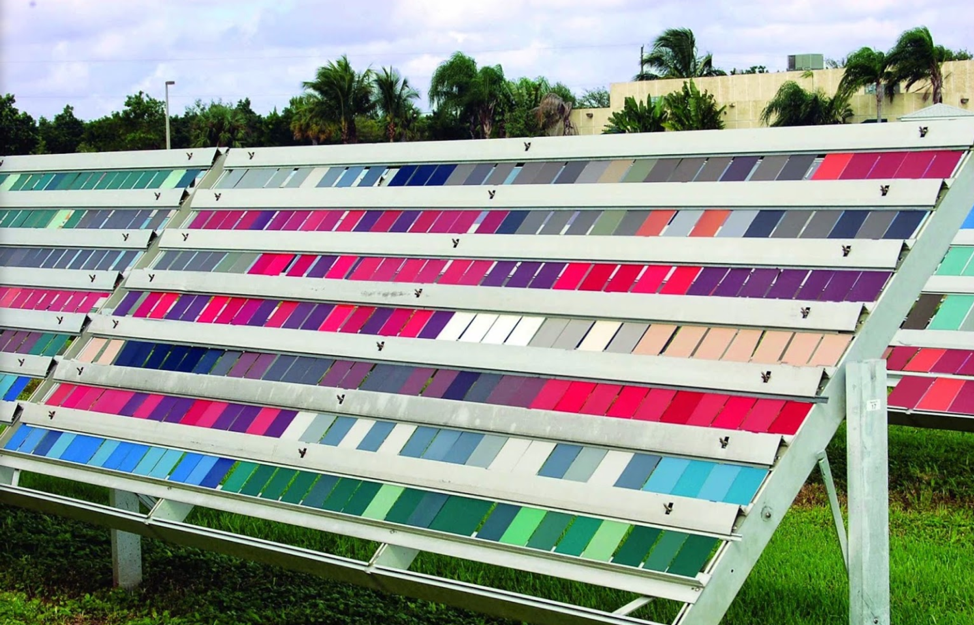

Glidecoat uses various colored gelcoat panels, as well as marine painted substrates for natural outdoor exposure testing in Florida:

Direct Exposure:

Specimens are securely mounted with their front surface facing the sun. Different exposure angles and mounting methods are used for different applications.

Salt-Accelerated Outdoor Corrosion:

Direct exposures with salt spray can produce fast and realistic corrosion, particularly for the coated metals/gelcoat surfaces.

Mildew Tests:

In this Florida exposure, panels are typically positioned at a 90º north to reduce sunlight, decrease surface temperatures, and increase moisture. In addition, specimens may be placed near or under vegetation to promote growth.

Accelerated Weather Testing:

Glidecoat uses a third-party company, to provide accelerated weathering tests. This device reproduces the damage caused by sunlight, rain and dew. In a few days or weeks, the tester can reproduce the damage that occurs over months or years outdoors. To simulate outdoor weathering, the accelerated tester exposes materials to alternating cycles of UV light and moisture at controlled, elevated temperatures. It simulates the effects of sunlight using special fluorescent UV lamps. It simulates dew and rain with condensing humidity and/or water spray.

Florida Materials Research Facility:

Here at Glidecoat, we utilize an outdoor subtropical exposure facility, which is the only commercial oceanfront facility for subtropical exposure studies in the U.S., and is rated among the most corrosive environments in the country.

Marine Submergence and Fouling Studies:

At this unique facility located in Ponce de Leon Inlet, we can monitor how our coatings interact with a wide spectrum of fouling organisms, including barnacles, mollusks, calcareous tube worms, bryozoa, hydroids and algae. The lab conducts marine submergence and fouling studies in both semidiurnal tidal waters of the Ponce de Leon Inlet and in a sophisticated filtered sea water system adjacent to the natural waters of the inlet.