Greg Hoffman is the owner of a 2004 32' Regulator with a dark blue hull. Greg splits his time between Osterville, MA and Deerfield Beach, FL. During the summer he works for one of Glidecoat's dealers, Oyster Harbors Marine. After seeing the results of the owners boat being coated with Glidecoat, Greg wanted to make the switch to ceramic coatings for his own boat.

- Model:

- 32' Regulator

- Year:

- 2004

- Length:

- 32'

- Location:

- Deerfield Beach, FL

Many boat owners are making the switch to ceramic coatings to protect their boats, but it is important to understand the cost comparison and benefits of ceramic coating vs wax. Greg is the perfect example to illustrate this comparison. Greg owns a 2004 32' Regulator with a dark blue hull. His boat is stored in a dry stack facility located in Deerfield Beach, FL. On average, Greg spends $3000 to have his boat hauled, buffed and waxed, three times a year.

While this might seem sufficient to protect the surface of his boat, the condition of the hull was very underwhelming. The biggest issue with traditional wax is that it does not bond with the surface, allowing it to evaporate and wear from the surface very quickly. This also allows the salt to work its way into the pores of the gel coat, causing stubborn water marks that can be extremely difficult to remove.

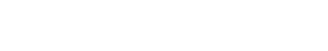

This is the exact problem that occurred to Greg's boat. Even though it had been recently buffed and waxed, then placed in storage, the boat had not been thoroughly washed so the dark blue hull was covered in deep water marks that had eaten into the gel coat.

Greg witnessed first hand the performance of Glidecoat's Nano Ceramic Coating over the course of the summer, after his boss Peter Maryott coated his boat in July. He saw the shine and gloss that the ceramic coating was able to provide, giving a better then new finish! And the continued protection it was able to provide throughout the summer, looking as good as the day it was coated.

Greg saw the opportunity to apply a product that is far superior to wax, providing better and longer boat hull protection, deeper gloss and shine, while saving at least 30% over the course of the year compared to what he was currently spending to maintain his boat.

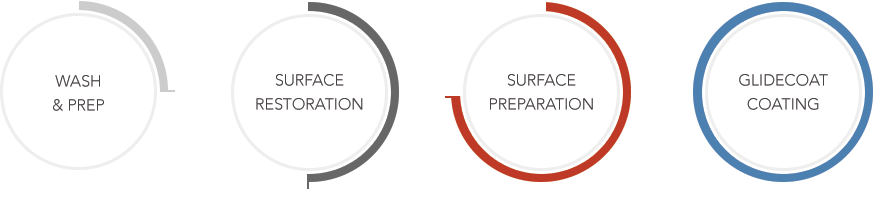

We began the process by washing the boat with Nano Wash to completely clean and ready for the next step. The second step included using a heavy cut compound with a rotary buffer at 900 rpm's to remove oxidization and hard water marks. In various areas throughout the boat, we had to repeat the compound several times to ensure the surface imperfections were properly removed.

The next step in the boat detailing process was to use Nano Compound with a foam pad at low speed. This product is unique because it helps to pull out stains that could not be removed with the cleaners and acids in the washing preparation. It also helped to further restore the shine.

Now comes the real transformation.

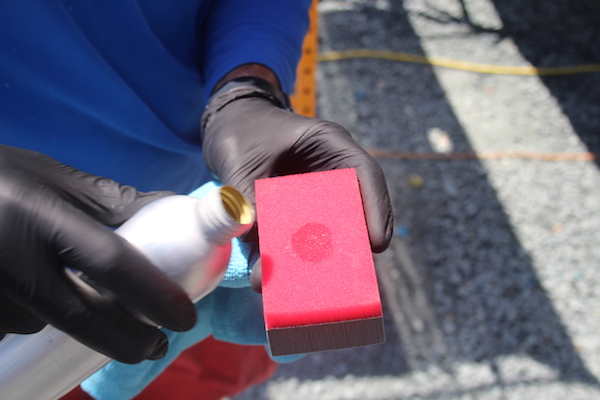

At this point we used Surface Wipe to wipe off all the areas to be coated. This step removes any further contaminants from the gelcoat and ensures we are working with a clean surface. With the surface now fully prepared and consistent we started the application of our nano coating.

By applying two coats of our liquid crystal, the coating will fill in all of the pores of the surface and after 8 hours of curing time, will create a protective barrier on the hull to prevent oxidization and hard water marks.