Joe is the original owner of this 2018 28' Whitewater and already after a year of ownership, has noticed several areas on the boat suffering from oxidization on the surface and in a constant battle, to keep the non-skid and other areas clean.

To address the issues, Joe began to research marine coating options in the market and based on our extensive experience, he reached out to our team to learn more about the marine coating application process and help protect his boat.

One of Glidecoat's goals when discussing a marine coating application with a boat owner is to understand the problems they are trying to solve. For Joe's boat, he wanted to remove the oxidization from the surface, add a higher level of protection, given he does not have a cover for the boat and help reduce his maintenance on the non-skid, metals, engine casings and the remaining flat fiberglass.

- Boat Brand:

- Whitewater

- Length Overall:

- 28'

- Ceramic Coating To:

- Hull sides (waterline & up), transom, top side including all of the metal & non-skid, top of the hard top & 2 engine casings

- Completion Time:

- 65 hours

- Location:

- Delray, FL

If you are researching the possibility for a marine coating application, one of the best times to get the application is when the boat is brand new, or just a few years old. In this instance, the application does not require extensive restoration work and helps minimize the cost.

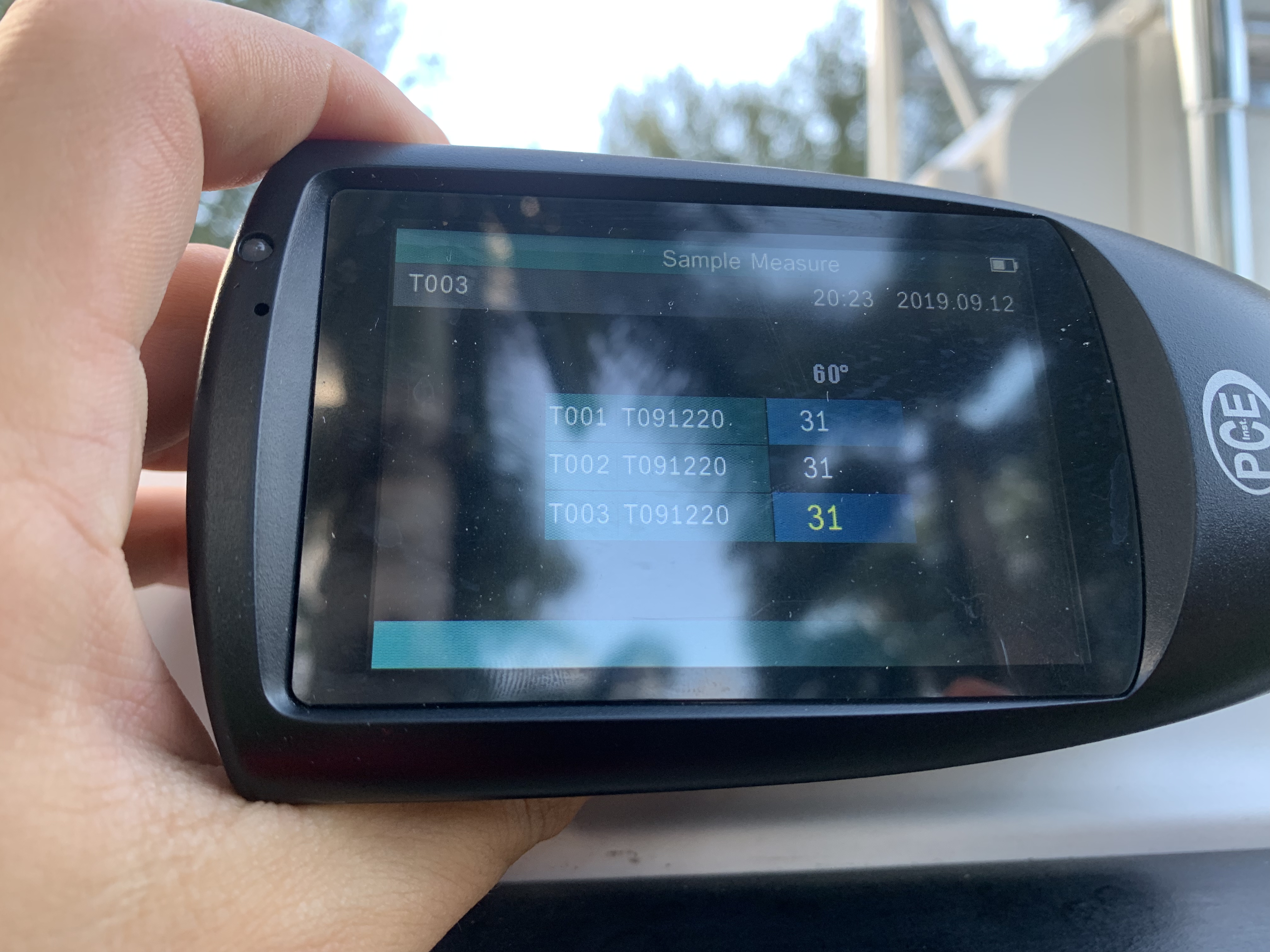

For this particular project, we had a few areas of concern, such as the gunwale rails that were already showing a medium level of oxidization with the gloss meter readings registering in the low 30's. Typically, the gunwales are one of the worst areas on a boat for sun damage and require several restoration steps and a added layer of marine coating to protect this area moving forward.

Marine Coating Process

Considering this particular boat had varying gloss meter readings in areas across the boat, we had to adjust our restoration process based on particular sections. For instance, with the noticeable oxidization along the gunwales, we had to complete a 7 step marine coating application process. This included the use of wool pad and medium compound, then downgrading to two additional buffing steps with our Rupes polisher.

Joe does not currently have a cover for his boat and due to the gunwales are a highly sun exposed area, we applied three coats of the marine coating to this section to provide high level of protection to fight off oxidization.

5 Step Marine Coating Process To Remaining Areas

For the remaining areas on the boat, that had gloss meter readings in the 60's to the 70's, we could use our 5 step marine coating process by buffing the surface twice with our medium grade nano compound, followed by our nano polish to bring those gloss meter readings back and beyond factory new before proceeding forward with the marine coating.

As you will see below, the boat turned out amazing!