Skip recently purchased a brand new 31 Catamaran Center Console from Renaissance Prowler. After making a substantial purchase, Skip started researching to find a professional ceramic coating to help protect his investment.

Skip used the popular boating forum, The Hull Truth, where boat owners across the country share their experiences and feedback about anything and everything related to boating. He came across Glidecoat on The Hull Truth, with several members discussing their positive experiences with our ceramic coating and how it has helped properly protect their boats.

Skip reached out to us directly to have us apply our professional ceramic coating on his 31 Prowler Catamaran at the factory before taking delivery of his new boat.

- Model:

- Renaissance Prowler

- Year:

- 2018

- Length:

- 31'

- Location:

- Opa-locka, FL

Glidecoat’s professional ceramic coating is the perfect product for any boat, whether it is used or new. The optimal time to have ceramics applied is when the boat is brand new. The ceramic coating benefits include:

• Preserving and protecting the integrity of new gel coat or paint

• Increasing the factory gloss and shine by at least 15%

• Extending the life of the gel coat or paint

• Reducing maintenance

• Protecting the surface from UV damage

• Greatly reducing the risk oxidization on the surface

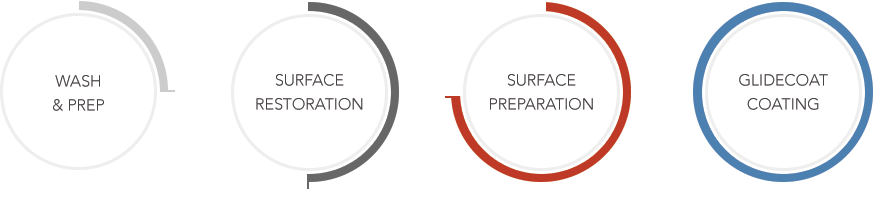

With our professional ceramic coating application process, the preparation is key! The coating is designed to enhance and protect the surface to which it is applied, so the boat must be prepped to the best condition possible.

The 31' Prowler boat was due to be delivered to the client and remained at the manufacturer's facility in Opa-locka, FL. Considering the facility is fully operational with dust and other particles in the air, the first step was to wash the entire boat with Nano Wash, and remove any dirt from the surface before polishing.

Once the hull was completely washed and dried, we then started the process of polishing the hull and topside to increase the gloss meter readings.

We then polished all flat fiberglass surfaces, both on the hull and the topside. This step was necessary to remove any residual mold release wax, while eliminating any surface imperfections and improving the shine. Immediately prior to applying Glidecoat’s professional ceramic coating, we used our Surface Wipe to decontaminate the surface.

Now comes the real transformation.

We start by pouring a dime sized amount of our professional ceramic coating onto the red application sponge. Working in 2’ by 2’ sections, we apply our coating onto the surface. When applied the surface will appear to be “sweating”, we then buff the area with a clean microfiber cloth, working the coating into the pores while removing any excess liquid from the surface. This process is completed across the entire boat. Once the first coat is completed, we repeat this step and apply a second coat of the professional ceramic coating.