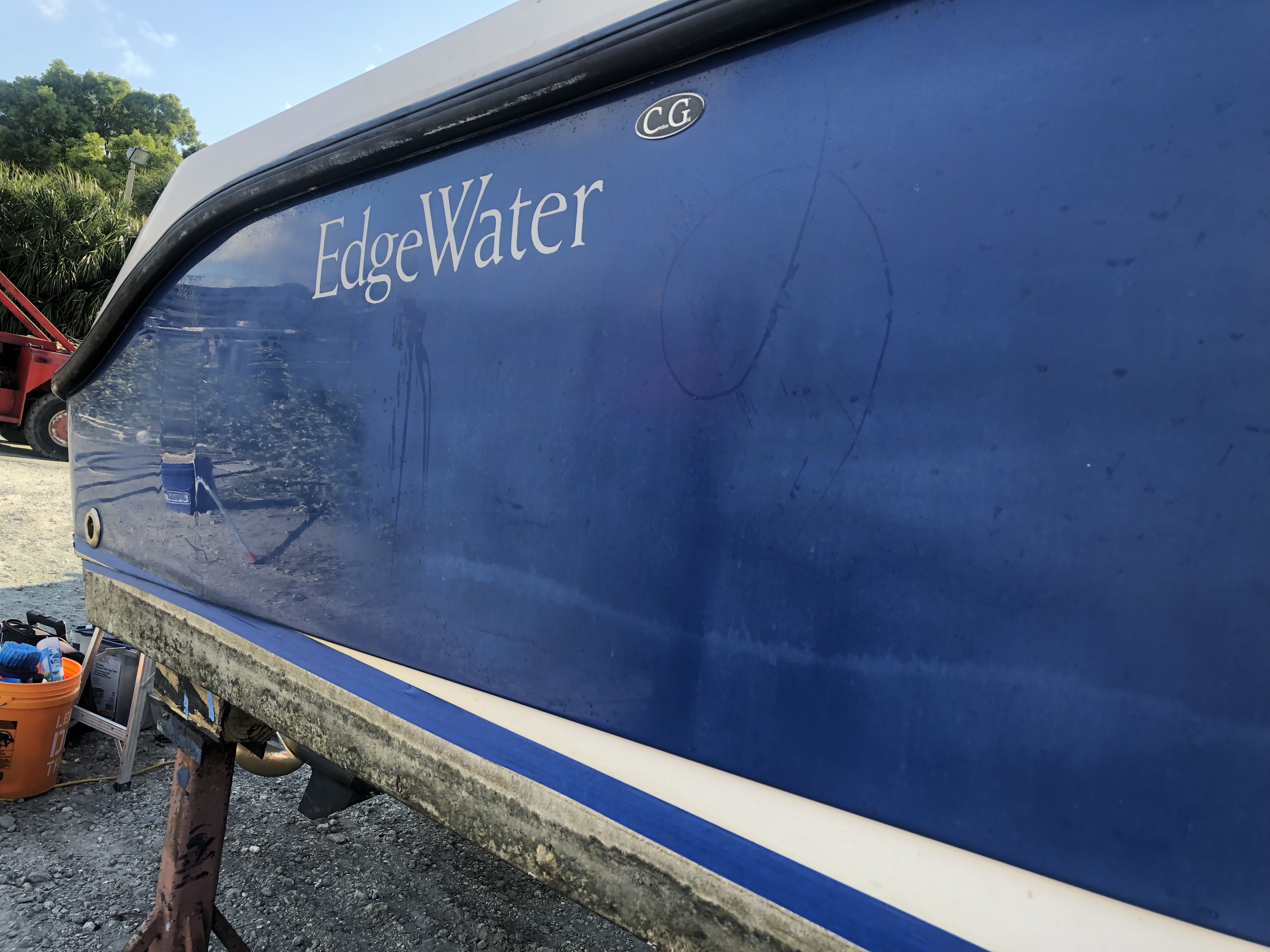

Jeff, the owner of this 2005 26' Edgewater had significant oxidization issues with the dark blue hull here in South Florida. He was researching for the best solution to bring his boat back to life. First, he thought about painting the boat, but after learning about the high cost of painting, he wanted to find an alternative.

Marine ceramic coatings are a perfect solution to bring the dark blue gel coat to life and lock down the surface. And, most importantly, for this particular case, a cheaper alternative to boat painting.

During the initial discussion with Jeff, he mentioned receiving a quote of over $3,000 to paint the hull of his 2005 26' Edgewater and wanted to learn about other options to reduce the expense of restoring his boat.

Our team shared with Jeff our prior experience with numerous other older boats we encountered the same challenge. A perfect example, was our work on Dean's 2003 29' SeaVee, which he was also looking to have the boat painted.

Applying the Glidecoat marine ceramic coating was a better fit for Jeff, for three main reasons;

1). The restoration and marine ceramic coating application would be completed within 1 day. Whereas, with boat painting, his boat would be out of commission for several weeks

2). Significant savings for applying ceramic coating on gel coat vs boat paint

3). The finished results will give the appearance of a new paint job

- Boat Brand:

- Edgewater

- Length Overall:

- 26'

- Ceramic Coating To:

- Hull

- Completion Time:

- 22 hours

- Location:

- Pompano Beach, FL

This 2005 26' Edgewater had severe oxidization on the dark blue hull and would require significant restoration to bring back the color of the gel coat. Fortunately for the owner, the surface still had sufficient gel coat, which gave us the ability to remove the oxidization and still have enough gel coat to lock down the surface.

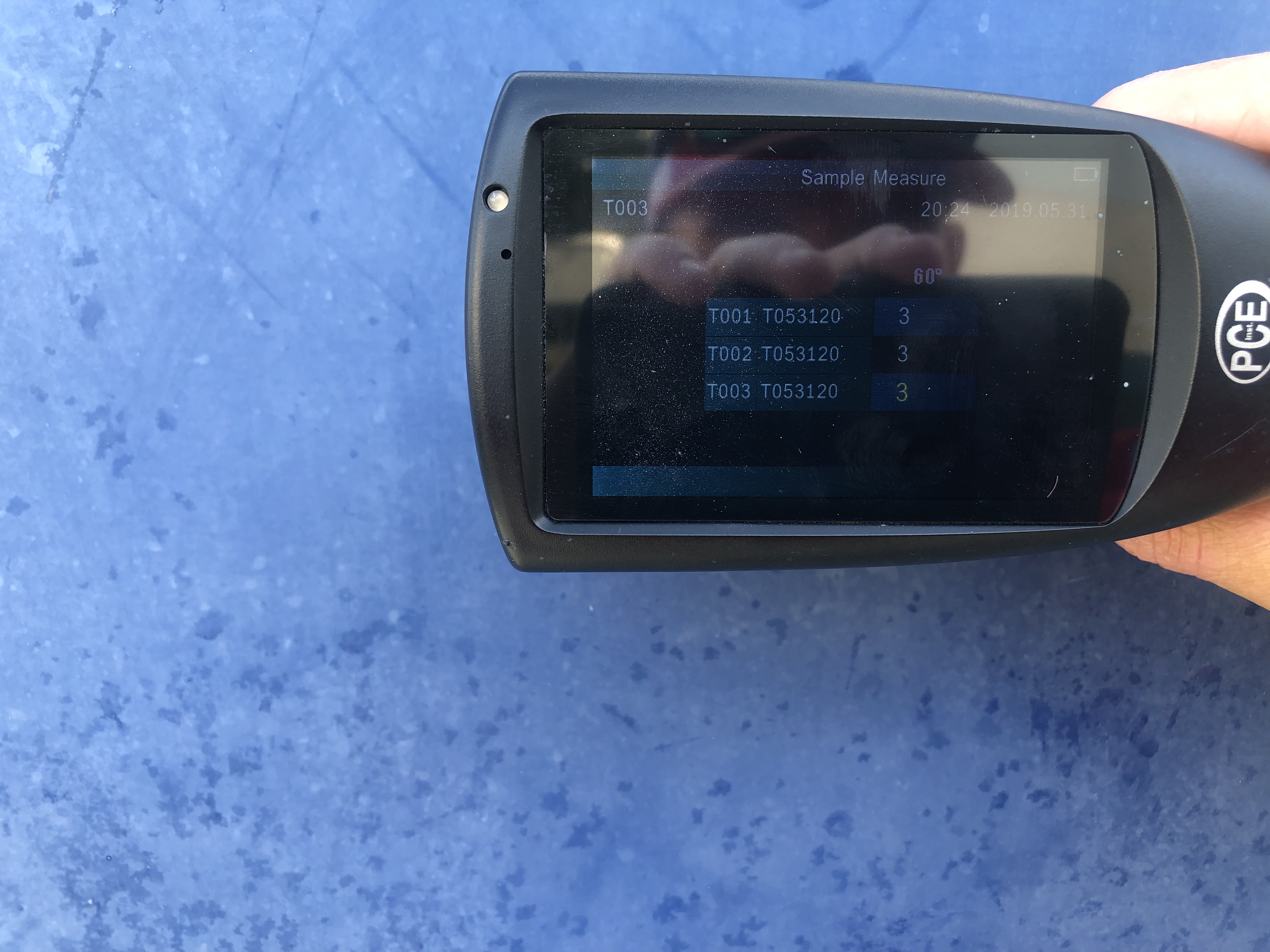

One of the indicators we use to measure the current condition of the surface is a gloss meter. Factory new gel coat will typically register between 82 - 88 on the gloss meter. Whereas, with this oxidized hull, the gloss meter readings registered as low as 3.

Due to the heavy oxidization, extremely low gloss meter readings, noticeable scratches in the surface and salt deposits in the gel coat the prep is key to the finished results.

The Success Of The Project Is In The Prep

To be successful with a marine ceramic coating application, the prep work is vital. Typically, older colored boats are the most challenging to work with to bring back to life. For this particular project, we were required to complete several additional prep steps before applying the ceramic coating.

As a result of these steps, customers are usually surprised how much more steps we complete than your traditional buff and wax. For this boat, we completed the following steps;

1). Acid wash with On Off to remove the salt build up on the surface

2). Complete rinse, wash and use of soft foam brush to remove any removing On Off and other contaminants on the hull

3). Two buffing steps with heavy compound and a wool pad

4). One buffing step with medium grade compound and a medium grade foam pad

5). One buffing step with polish and soft foam pad

6). Sterilize the hull with Surface Wipe

7). Apply two coats of marine ceramic coating

Why Is Prep So Important

marine ceramic coatings bond directly to the surface and will lock in the condition of the surface applied to. So, if you applying the marine ceramic coating over the heavy oxidization, you would be simply locking in that condition.

Since, the level of protection is significantly more than a traditional wax, ceramic coating applicators must be more thorough with the prep to ensure the best condition before applying the coating.

Fortunate for us and our customers, the end result is always worth it....just check out those after photos below!