Roger owns a 2017 380 LXF Scout with a beautiful black hull. As other boat owners with colored hulls understand, they can look amazing, but they can be a real pain to keep clean. Roger had recently learned about the benefits of ceramic coatings, but like many consumers, he didn't know how to select the best ceramic coating for his boat.

- Brand:

- Scout

- Length:

- 38'

- Location:

- Fort Lauderdale, FL

As ceramic coatings become more popular in the marine industry, many companies and detailers are starting to provide ceramic coatings as an alternative and better solution to wax. While it is always good as a consumer to have options when making a purchase, it is important to know a few things when trying to select the best ceramic coating for your boat.

Ceramic coatings have been around for over 10 years in the automotive industry, and it is only recently that they have gained traction in the marine market. Given the origins of ceramic coatings, many companies that offer an automotive ceramic coating have begun to offer a marine coating.

In many cases the marine coating will be the same or very similar to the automotive. These coatings will work to an extent, providing high gloss and a hydrophobic surface, but they will not last in a marine environment.

The lack of longevity of a automotive ceramic coating on a boat, is due to numerous reasons;

• The different type of surface - painted aluminum is a less porous surface than gel coat and painted fiberglass. As a result, the percentage of solids for the ceramic coating must be greater, to fill in the pores of the gel coat and painted fiberglass.

• High and constant exposure to salt - salt is one of the biggest culprits that cause oxidization to the hull of your boat

• Higher exposure to UV damage - have you ever noticed how tired you are after a day out on the boat and reflection of UV rays from the water. Just think how your boat is consistently battling that challenge, day in and day out. This exposure is more intense than what your car experiences. As a result, the ceramic coating must be stronger to protect from sun damage.

At Glidecoat, we have tested, developed and optimized our coatings to perform best in the marine environment, ensuring our customers will get a coating that lasts, backed by our 18 month warranty. This is a key factor when trying to choose the best ceramic coating for your boat.

Before reaching out to Glidecoat, Roger had his local detailer working on the boat. His detailer was applying a competitive ceramic coating to the black hull of the 38 Scout. After learning more about the product that was being put on his boat and not a ceramic coating optimized for marine, Roger had his detailer stop the project. He then reached out to Glidecoat, to have us remove the existing ceramic coating and complete the project with Glidecoat's Ceramic Coating.

Ceramic coatings are a great solution to protect the boats surface from the harsh elements, repelling UV rays and not allowing salt and acid rain to penetrate the pores. When a boat is treated with a ceramic coating, the surface becomes very hydrophobic. This allows you to simply hose the boat down with water, rinsing away the salt, dirt, or fish blood from the surface.

When we arrived at Roger's boat, the black hull was covered in salt. We began to wash the boat with Nano Wash to remove the salt, allowing us to see the real condition of the gel coat. It was easy to find the areas that had been previously coated with the competitive coating, based on how the water acted on the surface.

The surprising thing that we found after washing the boat was the amount of salt deposits in the gel coat, across the entire hull, even the areas coated with the competitive ceramic coating. These salt deposits are where salt penetrated the pores of the gel coat, creating hard water marks that are extremely detrimental to the surface and difficult to remove.

It was clear that the coating previously used was not strong enough to withstand these harsh conditions.

In order to remove the salt deposits, we used CLR, to flush out the salt from the pores of the gel coat, which could not be fully achieved from buffing.

Before the surface restoration we used a gloss meter to measure the shine of the surface, on areas coated with a competitive product and the non coated areas.

Those areas of the hull which had been coated previously averaged in the low to mid 80's, which was not that much higher than some of the non-coated areas, although there were non-coated sections that averaged in the high 50's.

Once the surface was free of salt and the hard water marks, we began the removal of the previous ceramic coating and surface restoration. Note most ceramic coatings come off through abrasion (buffing), whereas some require wet sanding. When dealing with a newer boat with little to no oxidization, our main goal in the surface restoration step is to remove any minor surface imperfections (scratches, water marks, etc) while increasing the gloss of the gel coat.

We used our Nano Compound with a light cutting foam pad to remove the leftover water marks and bring an added depth to the gloss of the black hull.

Now comes the real transformation.

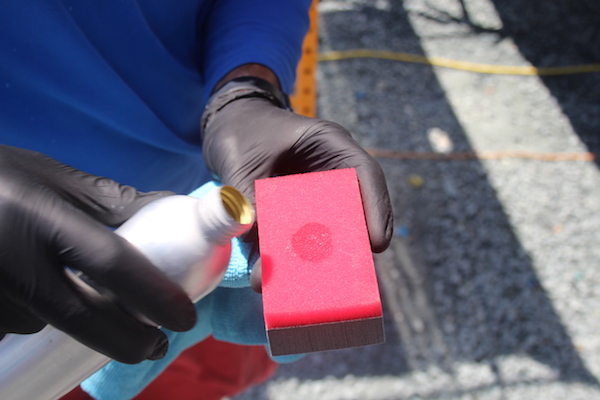

At this point, we have finished the restoration process to bring back the shine and color of the hull. Before applying our gelcoat ceramic coating, we use Surface Wipe, our version of a denatured alcohol to sterilize the surface and ensure all contaminants are removed from the surface.

With the surface now fully prepared and consistent we started the application of our gelcoat ceramic coating.

Applying two (2) coats of our gelcoat ceramic coating, the coating will fill in all of the pores of the surface and after 8 hours of curing time, will create a protective barrier on the hull to prevent oxidization and hard water marks.

After the curing process, the hull of the boat looks like glass!