How Glidecoat Inflatable Coatings Can Help.

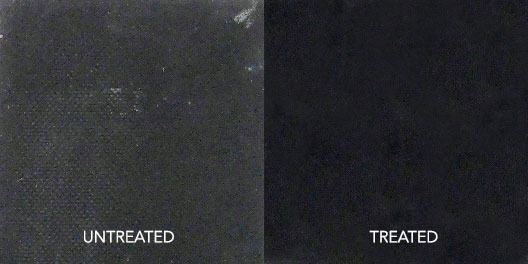

The solution to these issues is Glidecoat Inflatable. The product uses our Smart Surface Nano Technology to fill all the microscopic pores of the fabric (either CSM or PVC) to create a smooth surface that reflects water, dirt, and salt. The Smart Surface technology also increases the tolerance against damage and leaks that are a result of soft impacts and abrasion. Glidecoat’s Nano Polymer technology protects against damage from UV and heat by reflecting UV rays and making the rubberized fabric more resilient to expansion from heat. Independent lab results show that after one year of high intensity UV, Glidecoat Inflatable reduced color and gloss fading by 45% along with eliminating drying, cracking, and adhesive separation. Also, Glidecoat increased the life of PVC that was left uncovered on 500 hours of intense UV rays comparable to 1 year in South Florida by 30%.

By filling in the pores, Glidecoat Inflatable stops moisture from absorbing into the boats rubberized fabric material and eliminates mold and stains. Now you can cover and store your inflatable boat without the concerns of mold and moisture damage. Glidecoat Inflatable has proven to extend the life cycle of Hypalon and PVC inflatables by 25%.

In addition, the Glidecoat offers the Inflatable Hard Bottom Kit which allows you to cover the Fiberglass bottom, thereby protecting it from marine growth.

- Glidecoat Inflatable Benefits

- Prevents color fading and UV damage by 45%

- Reduces adhesive failures

- Increases material resilience to heat expansion

- Prevents leaks and damage from soft impacts

- Increases life cycle of material by 25%

- Prevents mold and dirt staining

- Increases the life cycle of a PVC tender by 30% when left expose to the sun