The team at Seven Seas Yacht Sales reached out to us on the opportunity to restore a highly oxidized 35' black hulled Scout with our ceramic coating.

The five year old Scout had been neglected from routine maintenance and the color of the hull has suffered severe oxidization from the harsh South Florida elements.

- Boat Brand:

- Scout

- Year:

- 2014

- Length Overall:

- 35'

- Location

- Ft. Lauderdale, FL

Dark colored hulls present a significant challenge for boat owners to keep clean, prevent sun and salt damage, which typically leads to routine buff and wax jobs. Len at Seven Seas Yacht Sales contacted us after watching first hand the application process of another 38' Black Hulled Scout and the tremendous advantages of a ceramic coating to protect the black hull.

As we illustrate in all of our case studies, videos and other documentation, the prep work is essential to be successful with a ceramic coating application.

This 35' Scout presented the tough challenge of dealing with severe oxidization and porous surface.

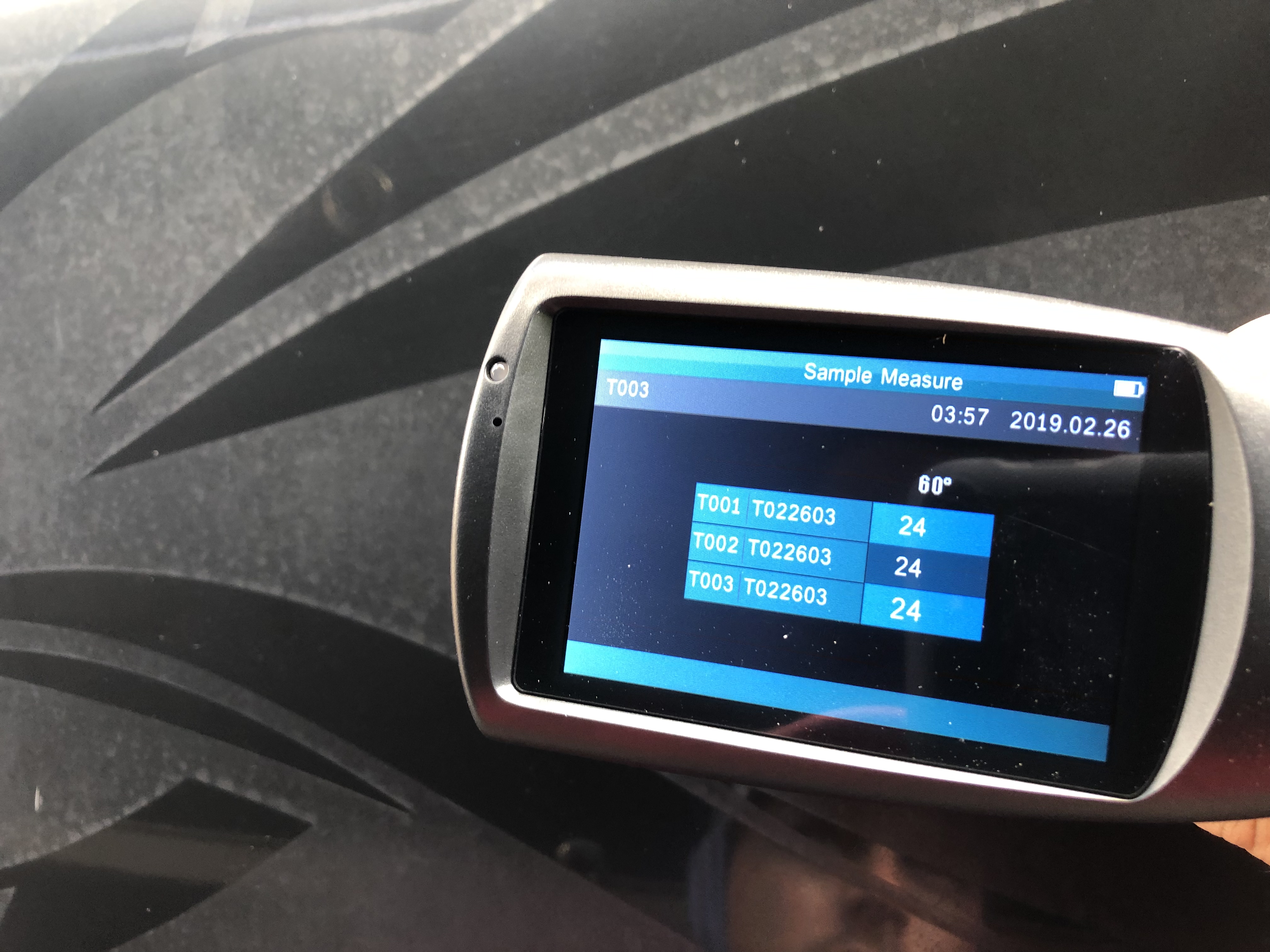

Due to the condition of the black hull, we had to complete several additional steps to the ceramic coating process. As you saw in the photos above, the first step any time we work on a boat, is to take photos and gloss meter readings.

We use those photos and gloss meter readings for numerous reasons;

1). Use in the case studies to show the transformation of the boat from before and after

2). The gloss meter readings gives us an indication of how much restoration is required and if the readings meet our standards

Our goal on each boat is to get the readings as high as possible and most cases reach the mid 80's to even higher than 100.

For a typical Glidecoat ceramic coating application, we complete 6 steps. Those steps include;

1). Wash

2). Compound

3). Polish

4). Sterilize the surface

5). 1st ceramic coating application

6). 2nd ceramic coating application

With the heavy oxidization to the black hull boat, we were forced to complete these steps in order to achieve gloss meter readings of 88.

1). Wash

2). Heavy compound with a wool pad

3). 2nd pass with heavy compound with a wool pad

4). Medium compound with firm foam pad and random orbital

5). Medium compound with soft foam pad and random orbital

6). Sterilize the surface

7). 1st ceramic coating application

8). 2nd ceramic coating application

9). 3rd ceramic coating application

This boat presented a rare instance we were required to complete a third ceramic coating application to the hull. This was direct result of the how porous the surface was.

During the first application of the ceramic coating, the coating had not fully filled in the pores of the surface and a result, required an additional coat.