At Glidecoat, we have been focused on the development of smart surface science solutions for several years.

Over that time we have worked with various companies within the Nano technology coatings market as well as our own chemists and have developed a variety of coatings, which leverage this technology across running gear, gel coat, metal surfaces, aluminum, PVC, fiberglass and numerous other substrates.

What is a Nanotechnology?

Nanotechnology is science, engineering, and technology conducted at the nanoscale, which is about 1 to 100 nanometers.

There are 25,400,000 nanometers in an inch and a human hair is approximately 80,000-100,000 nanometers wide.

On a comparative scale, if the diameter of a marble was one nanometer, then the diameter of the Earth would be about one meter.

Nanoscience and nanotechnology involve the ability to see and to control individual atoms and molecules. Everything on Earth is made up of atoms—the food we eat, the clothes we wear, the buildings and houses we live in, and our own bodies.

But something as small as an atom is impossible to see with the naked eye. In fact, it’s impossible to see with the microscopes typically used in a high school science classes. The microscopes needed to see things at the nanoscale were invented relatively recently—about 30 years ago.

Once scientists had the right tools, such as the scanning tunneling microscope (STM) and the atomic force microscope (AFM), the age of nanotechnology was born.

Although modern nanoscience and nanotechnology are quite new, nanoscale materials were used for centuries. Alternate-sized gold and silver particles created colors in the stained glass windows of medieval churches hundreds of years ago. The artists back then just didn’t know that the process they used to create these beautiful works of art actually led to changes in the composition of the materials they were working with.

Today’s scientists and engineers are finding a wide variety of ways to deliberately make materials at the nanoscale to take advantage of their enhanced properties such as higher strength, lighter weight, increased control of light spectrum, and greater chemical reactivity.

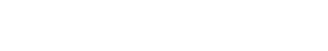

Nanoscale materials have far larger surface areas than similar masses of larger-scale materials. As surface area per mass of a material increases, a greater amount of the material can come into contact with surrounding materials, thus affecting reactivity.

Structures and properties of materials can be improved through the nano processes. Such nanomaterials can be stronger, lighter, more durable, water-repellent, anti-reflective, self-cleaning, ultraviolet- or infrared-resistant, antifog, antimicrobial, scratch-resistant, or electrically conductive, among other traits.

By taking advantage of these properties, today’s nanotechnology-enabled products range from baseball bats and tennis rackets to catalysts for refining crude oil and ultrasensitive detection and identification of biological and chemical toxins.

In Glidecoat’s case we have used this technology to develop some of the most advanced coatings in the market, specific to the harsh and demanding environments of the Marine Market

*individual results may vary depending upon the initial condition of the surface being treated.