The SeaVee had been sitting at the same dock in South Florida for 13 years, facing north, with the starboard side facing the dock and the portside exposed to unrelenting sunshine. The boat has had very little maintenance done and had not shown a luster for more than 4 years. The boat was wet sanded 4 years ago and this had removed a significant portion of the gel coat.

The owner was considering painting the boat at a cost of nearly $10,000 until he happened across Glidecoat’s Professional Top Coating process.

- Model:

- SeaVee

- Year:

- 2003

- Length:

- 29'

- Location:

- South Florida

The boat was not on a regular wax/detailing schedule and had not shown a luster for more than 4 years. The props, running gear and hull were cleaned by a diver on a monthly basis, but beyond that, very little maintenance had been down.

The yellow hull on the port side had considerable fading. There were areas where the white undercoat was showing through. There was also no consistency in the color with some areas showing fading more than others.

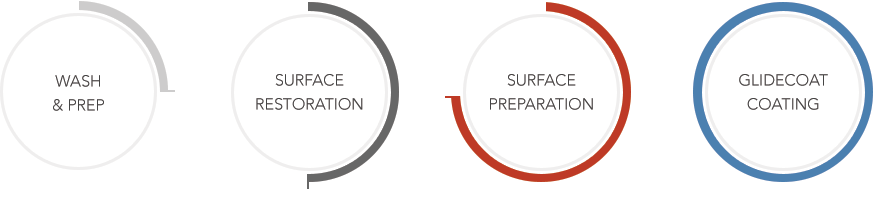

We began the restoration by applying a wash of heavy degreaser and given the heavy staining used an acid wash, which we normally refrain from as this makes the gel coat even more porous. The Glidecoat application is a hard coating, providing a glass like finish, so we needed not just clean the surface, but make it as consistent as possible.

The SeaVee boat was then washed with Glidecoat Nano Wash leaving a surface that was completely clean and ready for the next step. Glidecoat’s Nano Compound was then used to begin the process of restoring the gel coat. The Nano Technology provides an advantage over other compounds as it is able to penetrate deeply into the gel coat. A DA polisher was used with foam pads designed to enhance the cutting action of the compound to improve the result, but this step also cut the amount of time needed compared to a traditional buffer and wool pad.

The next step in the process was to use Glidecoat Nano Polish. This product is unique because it helps to pull out stains that could not be removed with the cleaners and acids in the marine washing preparation. It also helped to further restore the shine.

Now comes the real transformation.

At this point we used Glidecoat’s Surface Wipe to wipe off all the areas to be coated. This step removes any further contaminants from the gel coat and ensures we are working with a clean surface. With the surface now fully prepared and consistent we started the application of Glidecoat’s Top Coating.

The last and final step was to apply Glidecoat’s Prop Optimizer to the propeller and running gear.