Bret, the owner of this 2003 46' Sea Ray, was researching for better alternatives to the traditional buff and wax maintenance program.

After completing weeks of research about protective marine grade ceramic coatings and attempting to find certified dealers in his area, he got in contact with our service team. During his research, he discovered a wide range of prices from various detailing companies and ultimately selected Glidecoat and our protective marine grade ceramic coating to complete the work in Port Clinton, OH.

This case study will help highlight;

1). Why the prep work is essential for completing a protective marine grade ceramic coating application

2). How to handle the diamond cut non-skid

- Boat Brand:

- Sea Ray

- Length Overall:

- 46'

- Ceramic Coating To:

- Hull, Transom, Edge of the swim platform, Top of the T-Top and all exterior flat fiberglass near the bow and superstructure

- Completion Time:

- 79 hours

- Location:

- Port Clinton, OH

One of the challenges with older boats when quoting and completing a proper protective marine grade ceramic coatings application is evaluating the necessary steps and restoration time required to complete a thorough job.

When applying the Glidecoat protective marine grade ceramic coatings, it is required to always keep in mind that the prep work typically is 60 - 80% of the project as the ceramic coating will seal in the condition of the surface.

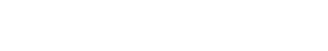

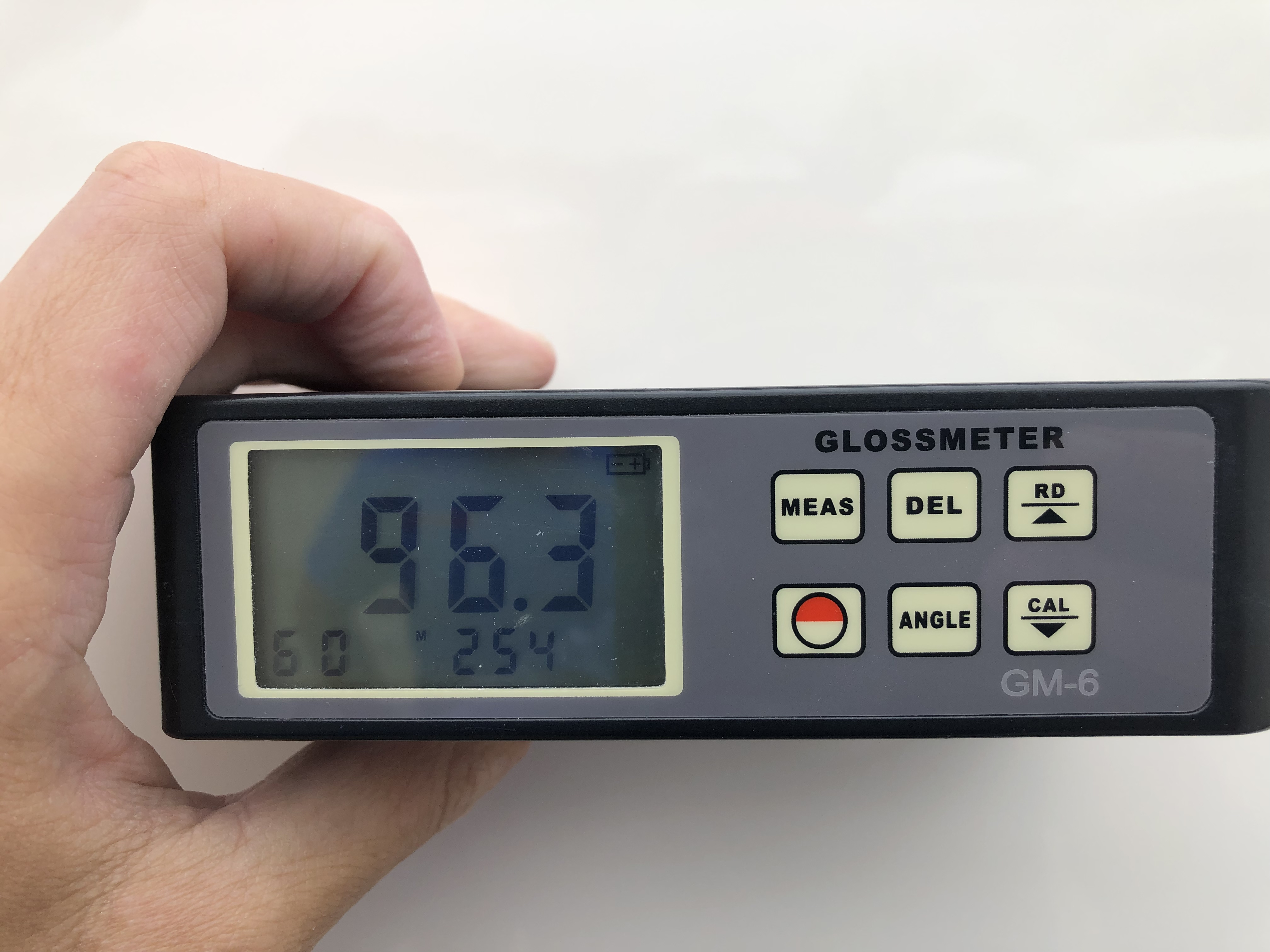

When we first arrived at the Sea Ray, we noticed across a number of areas on the boat was noticeable swirls marks from previous buff and wax jobs. As you can see in the photo below, is those swirl marks on the swim platform.

These swirls marks are typically caused by using an abrasive buffer and wool pads to quickly remove any oxidization from the surface. Using a Makita buffer with a wool pad as the first step is required at times, especially if you are dealing with older and/or oxidized boats.

In those cases though, it is important to downgrade the abrasiveness of your buffing by moving towards a dual action random orbital with soft foam pads to remove the swirl marks. This step is important to provide an awesome finish on the surface.

By adding in multiple buffing steps to address the correction work to remove those previous swirl marks can add several additional hours to the project. As an example, for just the hull of the 46' Sea Ray, the additional buffing steps added approximately 8 man hours.

The results are worth it though as you can see the mirror image shine on the hull after we completing the buffing, prep and ceramic coating application.

Corrective Work To Fix Those Swirl Marks

For the 46' Sea Ray, we started the restoration work by using our Makita buffer with a wool pad to remove oxidization from the surface. Then, we switched to our dual action random orbital Rupes polisher with a medium grade foam pad and medium compound.

When you are using the Rupes polisher, this step does add several hours to each side of the hull as you must be diligent and slow with your sections to achieve our intended results. The finish after looks impressive.

How To Handle Diamond Cut Non-Skid

More and more of our customers are asking about applying our ceramic coating to their non-skid. Bret was hoping we could provide him with a solution as his non-skid routinely got covered with debris from the yard, common use and tough to get out stains in the surface. Here was just a few spots when we first arrived to the boat.

For the older style non-skid like the pattern on Bret's boat, we would typically recommend a thorough deep clean with Soft Scrub, Spray 9 and our Nano Wash. By using the combination of these products, you will be able to remove those tough stains in the surface and get ready to apply the anti-slip deck coating.

From our prior experience with similar non-skid patterns, we typically advise the customer to use our Marine Shine & Shield product on the non-skid after cleaning because when attempting to apply our protective marine grade ceramic coatings, you end up using too much due to the porosity of the surface. This non-skid loves to soak up our ceramic coating.

Our Marine Shine & Shield

product is a great short term solution that provides better performance than your traditional wax and is easy for the boat owner to apply themselves every few months. This was the direction Bret decided to go with his boat by purchasing a few bottles of our Marine Shine & Shield and complete the work himself.