"After Hours" is a 52' Princess charter boat that does regular excursions throughout the Florida Keys and 5-7 day trips to Cuba. The Captain wanted to restore the original finish to the boat, which over the last 18 years, had been well maintained but definitely looked tired.

Goals

- Restore the boat's original finish

- Protect the boat's finish from UV and marine growth

- Restore the prop

- Boat Name:

- After Hours

- Captain:

- Kelly

- Manufacturer:

- Princess Motor Yachts, Plymouth, England

- Year:

- 1998

- Length:

- 52' 2"

- Height Above Waterline:

- 12' 9"

- Port:

- Key West, FL

The ‘After Hours’ was in fairly good condition when we were approached by Captain Kelly. This is a testament to how well Captain Kelly has maintained the boat over its many years of use. And this boat has definitely seen its fair share of use. Over the past 18 years, it has made many trips to Cuba from the Florida Keys. But even with the best maintenance efforts, the finish had seen better days. The area had significant UV damage and had lost a lot of its original shine.

In addition to restoring the finish, we were also tasked with the challenge of removing marine growth from the boat’s prop.

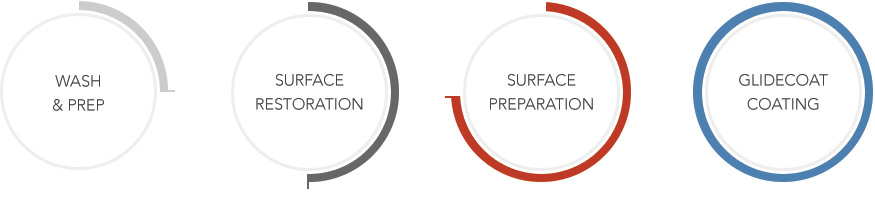

As part of the restoration process, the team initially washed the boat from stern to bow with Nano Wash. After thoroughly washing the boat, the boat was compounded using Glidecoat Compound. Once complete the boat was then wiped down with Surface Wipe which thoroughly removed any further contaminants. Once the decontamination process was complete, our accredited applicator applied Glidecoat nano ceramic coating to the hull, above the waterline and all surface areas, with the exception of the non-skid areas of the boat.

The props were sanded removing all marine growth. The surface was then cleaned using Glidecoat Surface Wipe and the Prop Optimizer was then applied, coating the props with four separate coats leaving 3-4 minutes between coats.